In the lean context, waste is any activity that does not lead directly to. As noted, it’s a methodology used to improve the quality of output in a process.

Free Training Lean Six Sigma Free Training

Six sigma comes from the bell curve used in statistics, where one sigma symbolizes a single standard deviation from the mean.

How does six sigma work in general environment. Establish business objectives and the role of six sigma to achieve those goals. This is achieved via a set of quality management methods, which feature both empirical and statistical approaches. The six sigma methodology has 5 key principles you can use when analyzing your processes.

As an organization, when you spend less time in fixing defective products, you will ultimately. More than 70% of the pollution prevention pays projects used lean six sigma in one year alone, according to the epa. Six sigma is about putting results on financial statements.

Process improvement is now part of the corporate culture. • new market for environmental improvement ideas: A sigma is a measure of standard deviation, abbreviated as small s, or the greek letter, σ.

Success of the effort is very highly correlated to the. Understanding the variety of factors that affect a business can direct how your. Six sigma follows a structured methodology, and has defined roles for the participants.

This means that the goal of lean six sigma is not to identify where the defect is, but to prevent defects from happening in the first place. Lean six sigma is a continuous improvement methodology for an organization. In addition, as noted previously, saying that lean and/or six sigma are the same as pollution prevention can lead operations personnel to dismiss the ideas of the environmental professional.

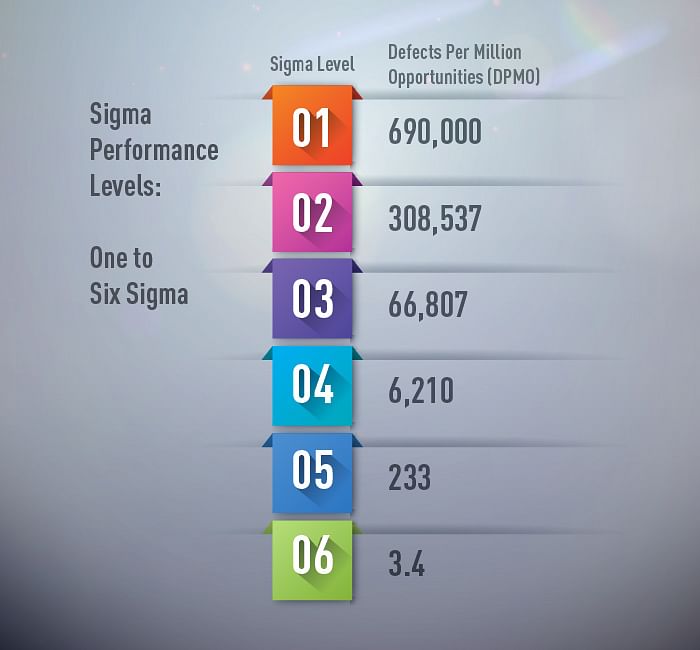

The company also is a leader in putting lean six sigma to use. The six sigma methodology includes statistical and quality management methods, as well as a results measurement tool and work teams dedicated to troubleshooting and improving business processes. In statistical terms, six sigma methodology reduces problems to 3.4 defects per million opportunities.

I am talking of a big team(300 ftes) that is involved in managing a two yr project in. Some key areas where six sigma can benefit an engineer include the following: Six sigma strategies seek to.

Six sigma methodology gained its popularity after the 90s when jack welch made it the main strategy of general electric. While typically associated with manufacturing, it can apply to any process requiring improved efficiency. The six sigma dmaic process.

In fact, the general electric company has claimed to have realized over $2 billion of cost savings from lean six sigma. The 5 key principles of six sigma. The lean six sigma methodology values defect prevention over defect detection.

So, we would expect organizational benefits. The main objective is to maximize the benefits for customers. Six sigma ( 6σ) is a set of techniques and tools for process improvement.

Introduced in its modern form in 1986, the approach improves quality of output by identifying and eliminating causes of defects. How can i implement six sigma in a project management environment? Hence, a business must understand the needs of their customers.

Meanwhile, edrawmax released the online version, it is worth to try! If the process has six sigmas, three above and three below the mean, the. In just five years, the company trained 55,000 in lean six sigma and launched more than 45,000 lean projects.

By better understanding the different types of customers. How lean and six sigma relate to the environment on their own, lean and six sigma efforts. In six sigma methodology, improvement of processes is its core objective which consists of dmaic (define, measure, analyze, implement and control).

In other words, there is little deviation from the standard and is within tolerance. Create an environment which enables success including goals, measures, coaching, and communication, among others. Organizations maximize performance and reduce product defects, which ultimately leads to higher profits.

Six sigma refers to a set of techniques and tools that help organizations improve business processes. It does this by first identifying, and then removing, the causes of defects. By connecting with lean and six sigma practitioners, environmental professionals can connect the wealth of environmental resources with those who are driving strategic and fundamental operational changes.

When communicating with operations personnel at businesses, a subtle approach to describing lean and environment may work best. A six sigma process is one in which 99.99966% of all opportunities to produce some feature of a part are statistically expected to be free of defects. There are many forces influencing how a business performs in the marketplace.

Let’s consider the nature of the benefits and their implication. Choose the symbols to form the matrix shapes in the library which is to the left of the canvas; Types of customers customers play a significant role in any business.

It was introduced by american engineer bill smith while working at motorola in 1986. Six sigma is a data driven methodology, and requires accurate data collection for the processes being analyzed. There are five main principles of six sigma:

Six sigma roles and responsibilities. The edraw six sigma matrix tool works on windows 7, 8, 10, xp, vista and citrix (for both 32 & 64 bit), mac os x 10.2 and later versions. The etymology is based on the greek symbol sigma or σ, a statistical term for measuring process deviation from the process mean or target.

When considering strategic business decisions, businesses analyze the six general environmental forces: Political, economic, sociocultural, technology, environment and legal factors. Actively participate in six sigma activities and projects.

To start, let’s define the term six sigma.